Abrasive belt grinding machines

A contact grinding machine from Loeser is extremely flexible.

The combination of basic machine and various attachment arms gives you dozens of possible uses for many purposes.

The LOESER contact grinding machine system

Here is the technical formula for success

When using 3 to 4 m long grinding belts, the patented 3-roll system ensures a constant and optimal belt speed no matter which contact disk diameter is used.

This means:

Pulled by the motor disk, the belt which is constantly tensioned at the grinding position allows for a higher degree of chipping at the same motor performance. The motor performance required by the LÖSER 3-roll system is 30% less than that of the conventional 2-roll support. Drive disks of 100 to 280 mm diameters provide the correct belt speed of 11 to 42 mtr./sec. This speed is adjusted to the specific work piece and entirely independent of the contact disk diameter.

When working with Scoth-Brite disks or belts or with felt polishing belts, the drive can be infinitely adjusted even for speeds as low as 3 mtr. /sec.

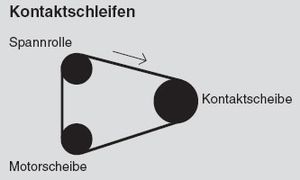

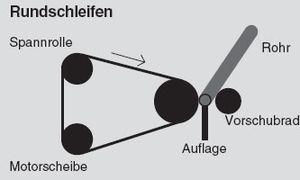

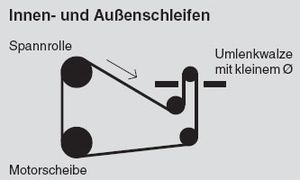

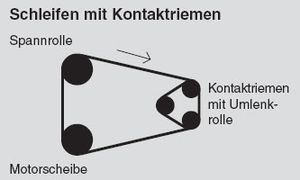

Due to the advantages offered by the 3-roll system, any required surface finishing is possible using contact disks from 50 to 400 mm, contact rolls or contact rollers from 15 to 50 mm, contact belts of 6 or 30 mm width, polishing brushes, polishing disks and polishing belts. A series of sophisticated grinding attachments for many applications offer solutions for grinding jobs that used to be almost unsolvable.

In addition:

With these grinding attachments, even trainees or assistants can perform the work of a qualified grinder.

In short:

LOESER abrasive belt grinding machines open up new fields of application for work pieces that in the past could not be processed with belt grinders at all.