Tube grinding machine, type KS 100-BA

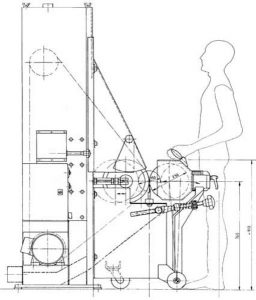

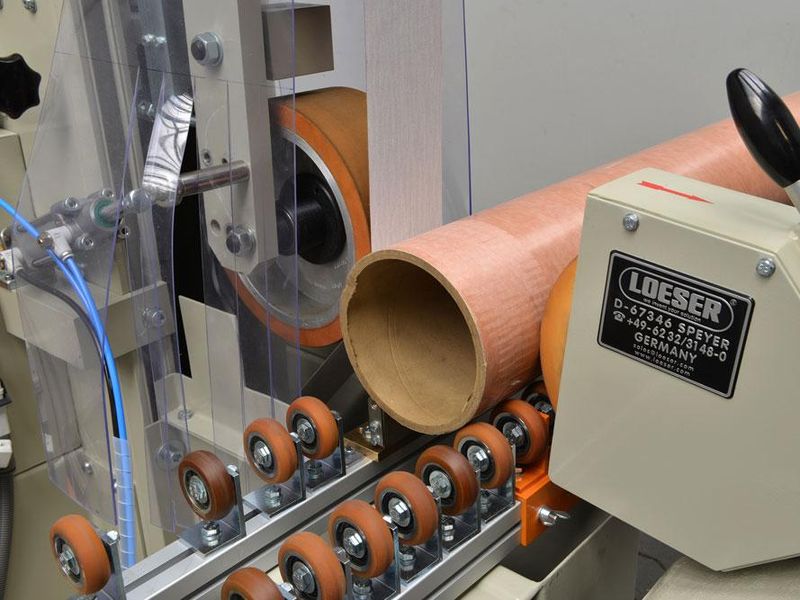

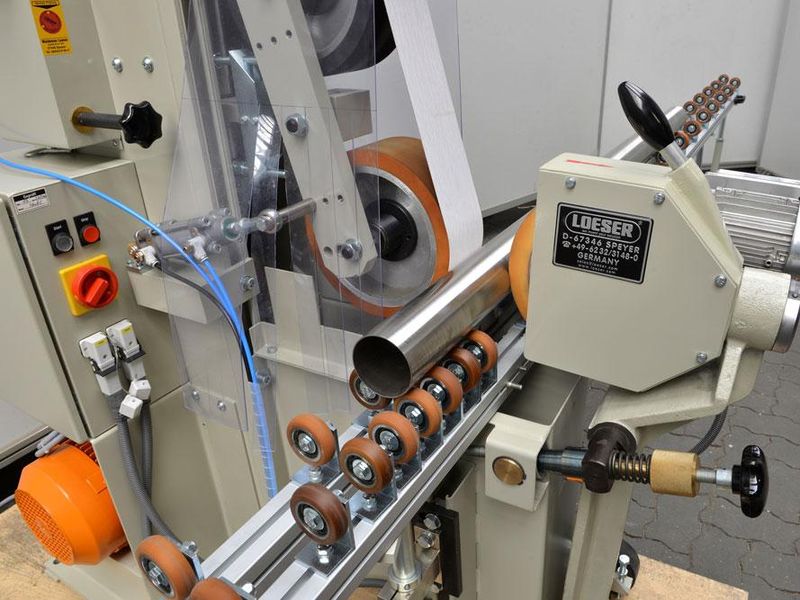

Basic machine KS 100 including BA attachment for centreless circular grinding of slightly conical and round components, tubes and solid materials as well as for plunge grinding of diameters from 5 – 180 mm.

For dry grinding of different materials. By means of the quick-changing system, it is possible to change from a hard contact disk for high removal to a soft disk for fine grinding within a very short period. It allows for the use of grinding, non-woven, and polishing belts.

A special polishing disk mounting further allows for the use of non-woven brushes and sisal disks for prepolishing with paste as well as of fabric polishing disks for glazing.

With a few steps and within a short period, the BA circular grinding device can be separated from the machine and used as a regular belt grinding machine.

Tube grinding machine, type KS 100-BA application videos

KS 100 BA with automatic balancing

Pipe-grinding-and-satin-finishing

- Technical specifications

- Data Sheets

| Motor | 3,2/4 kW |

| Belt dimensions | 75 or 100×4.000 mm |

| Speed of travel | 2 – 5 m/min. |

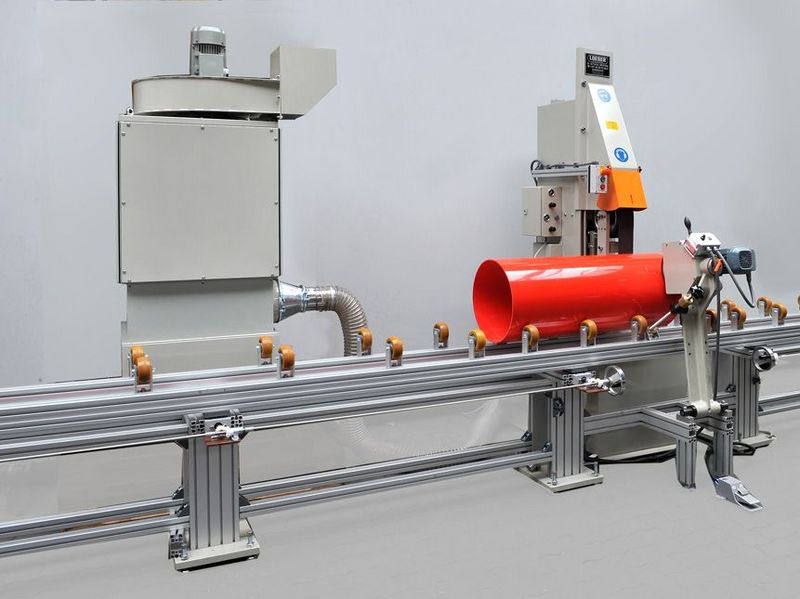

KS 100-BA special version

Overall equipment

Basic machine KS 100 including

3-roll roller table

Advantage: The roller table does not need to be adjusted therefore change-over times are short when changing diameters.

Adjustment: The diameter is adjusted by the machine and the circular grinding device only.

Available lengths: 2, 4, 5 and 6m